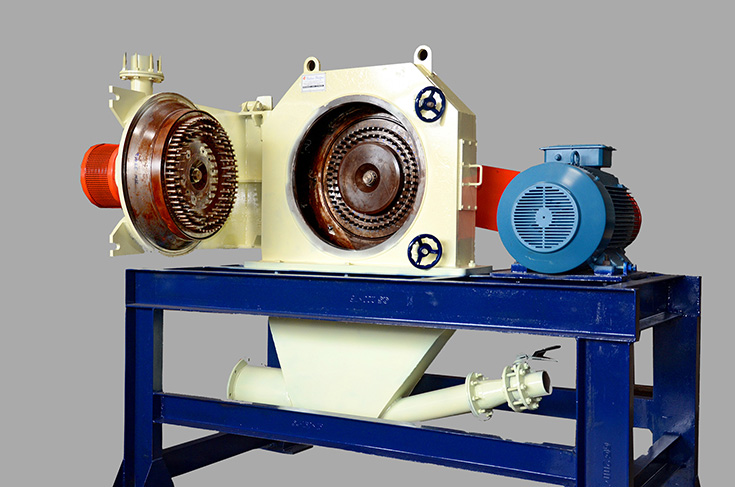

Pin Mill

Techno Designs has worked in the field of comminution for over 20 years and our pin mills have been developed based on such extensive experience in particle processing. Our Pin Mills can be universally used for grinding a variety ofmaterials. Pin Mills are used in minerals, food, chemicals, plastics and the pharmaceutical industry.

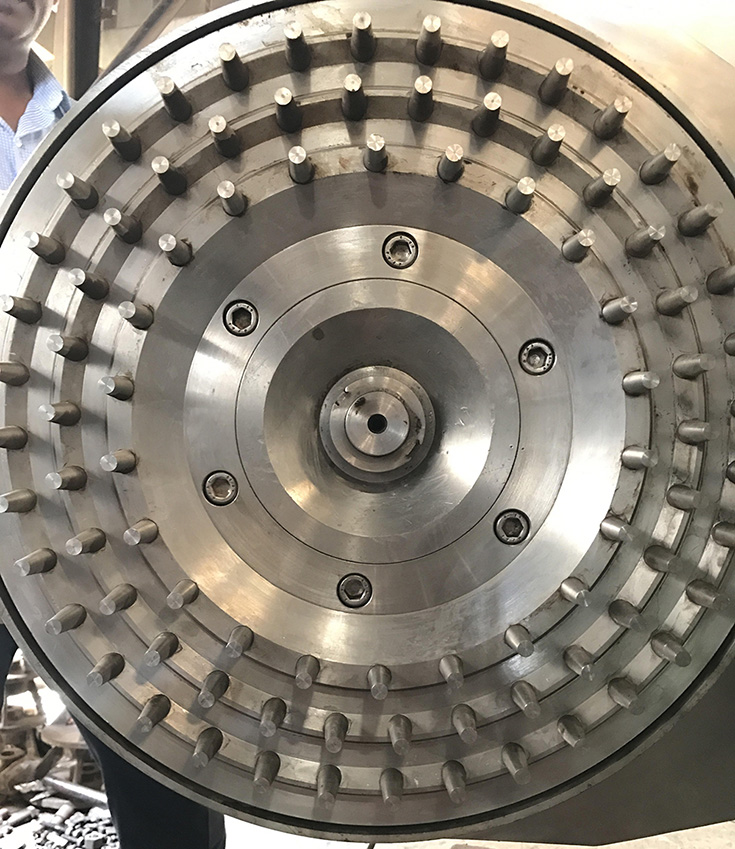

Material in a Pin Mill is fed in a centrifugal manner, and is gradually ground to finer sizes by impact crushing of the rows of pins. Depending on the product type, a fineness of 25 to 30µm can be achieved. Our counter-rotating pins provide excellent grinding results at much more economical costs.

Pins are driven by motors with a VFD control, which provides infinitely variable speeds and control over the required fineness of the product. Our pins are designed depending upon the required degree of fineness and the characteristics of the material to be processed. We can provide entire system with the necessary components for the comminution requirement.

SALIENT FEATURES:

- Robust housing construction with easy to open door.

- Easily replaceable pins allow hassle-free maintenance.

- Two direct mounted motors provide counter-rotation improving comminution efficiency

- Hardened pins available as option for both carbon steel and stainless steels to prevent wear

- High quality sealed bearings and precision manufacturing provide long service life ofthe pin mill.

For determining particle size distribution and grind ability of your product, we can conduct controlled trials on our test stand.

Technical Specifications for Pin Mills

| PIN MILL TYPE | PM 200 | PM 300 | PM 450 | PM 600 | PM 900 |

|---|---|---|---|---|---|

| Power (kW)* | 2 x 10 | 2 x 15 | 2 x 30 | 2 x 60 | 2 x 75 |

| Speed (RPM) | 0 to 10,000 | 0 to 8000 | 0 to 5000 | 0 to 3000 | 0 to 3000 |

| Dimensions | 1.5 x 0.7 x 0.7 | 1.7 x 0.8 x 0.8 | 2 x 0.9 x 0.9 | 2.8 x 1.5 x1.2 | 3.2 x 1.8 x 1.4 |

* Output and power can vary based on the type ofproduct feed and fineness

SPECIAL APPLICATIONS

Our Pin Mills are also available with the following accessories and configurations.

- Complete Stainless Steel buffed construction

- Flame proof/ Heavy-duty motors

- Cooling system for pre-cooling the material to avoid agglomeration or damage to the material

- Control Panel with HMI

- Feed Hopper with screw conveyor

- Complete integrated system with feeder screw conveyor, product hopper, bag filter, rotary valves and blower